You don't have any items in your cart.

Home Shop Sản phẩm Máy chế biến gỗ Máy phay gỗ - Cắt gỗ - Cưa Gỗ Automatic Wood Cutting Machine 1 Rails

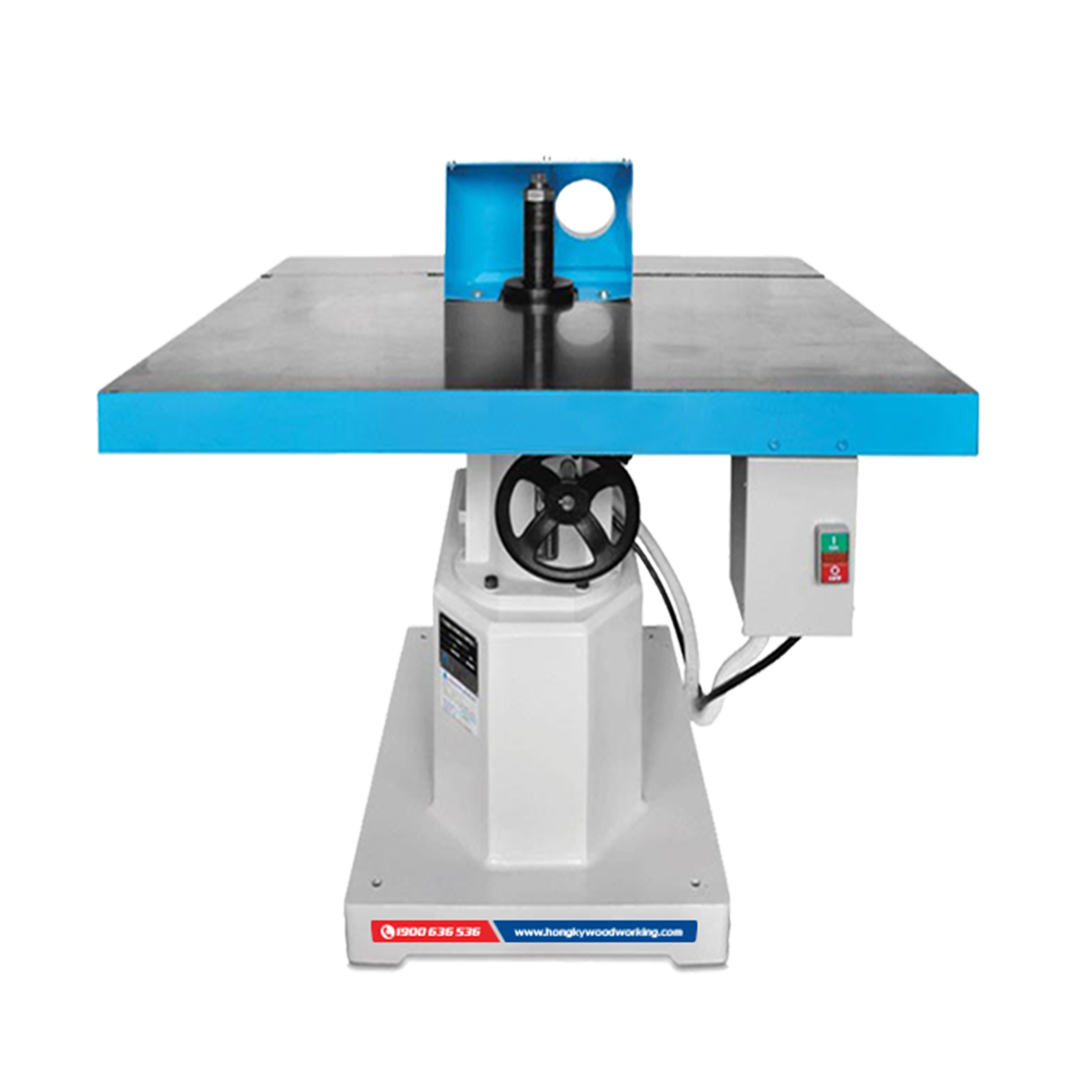

Automatic Wood Cutting Machine 1 Rails

Designed by Hong Ky, the Automatic Dual-Spindle Tenoning Machine is built to deliver optimal results in cutting and tenoning tasks. Made in Vietnam, this high-performance machine guarantees productivity for any wood processing enterprise.

- Dual-spindle automatic operation for high efficiency and output.

- Precision sliding table with ball bearings ensures smooth and accurate movement.

- Pneumatic clamping system for stable and automated cutting and tenoning.

- Adjustable cutting depth using an easy-to-operate hand wheel.

- Versatile milling spindles that accommodate various tenon profiles.

Overview

The Automatic Dual-Spindle Tenoning Machine is engineered for effortless processing of wood panels and timber joints. It’s ideal for cutting wood and creating tenons with accuracy. The robust cast iron frame provides unmatched stability, while the precisely machined milling spindle ensures consistent performance. Its pneumatic clamping system enhances workflow, enabling automated wood cutting and tenoning.

Features

- Durable Construction: A solid cast iron frame that increases stability and durability.

- High Precision: Smooth sliding table with ball bearings for precise movements.

- Automated Operation: Pneumatic clamping and dual-spindle mechanism for seamless cutting and tenoning.

- Easy Depth Adjustment: Effortlessly adjust cutting depth with the hand wheel for custom tenon profiles.

- Versatile Milling: Spindles that rotate for flexible milling angles.

Applications

This machine is perfect for use in woodworking factories, furniture manufacturing, and any industry requiring precise automatic wood cutting and tenon shaping. It performs exceptionally well in mdf cutting, timber frame construction, and furniture joinery.

Suitable Materials

- MDF boards

- Plywood

- Solid timber

- Composite wood panels

Contact Information

For export inquiries, please contact us at +84 909 073 505.

Technical Specifications

| Motor of finger spindle: | 2x5Hp-3phases-2P |

| Main spindle speed: | 5500 rpm |

| Motor of cutting spindle: | 4x3Hp-3phases-2P |

| Speed of cutting blade: | 2800 rpm |

| table traction motor | 1/2Hp-3phases-4P |

| Table pull speed (50Hz) | 9m/phút |

| Miximum working length: | 1200 mm |

| Maximum working width: | 550 mm |

| Cylinder for clamping the workpiece: | 02 |

| Machine dimensions (LxWxH): | 2246 x 2069 x 1350mm |

| Machine net weight: | 1080 kg |

| Working preasure of pneumatic cylinder: | 4 - 6 kgf/cm2 |

| Total power: | 16.875Kw |

| Timber species: Softwood / Hardwood | |

| Operating voltage: |

380V ± 5%, 50HZ |

User Manual

Updating...

Wood Saw Panel

Contact- Panel saw machine ideal for cutting large wood panels

- Heavy-duty, one-piece cast frame enhances durability and rigidity

- Smooth sliding table with ball-bearing guide for effortless operation

- Pneumatic clamping system ensures secure material holding

- Manual handwheel for precise depth adjustment and flexible cutting angles

Mortising Machine

Contact- High-precision ball rail system for smooth sliding motion.

- Powerful hydraulic clamping for secure material hold.

- Sturdy, vibration-free frame for consistent performance.

- Automatic table elevation and workpiece clamping.

- Simple setup with coordinate-saving technology for repeat jobs.